Extremely high traction with precise control of wheels/caterpillars

|

IntEn controller provides high torque with low voltage Permanent Magnet Synchronous Motor (PMSM). PMSM motor can provide precise shaft positioning as compared to asynchronous ones |

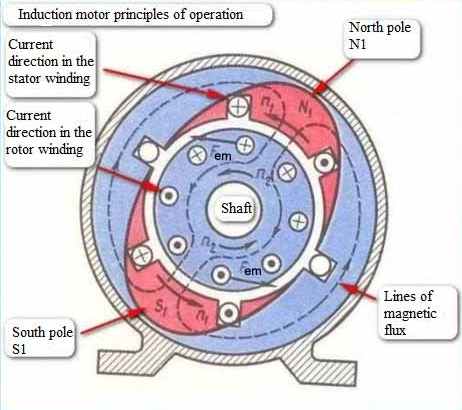

The modern EV applications usually use asynchronous electric engines for high tractive force vehicles. It’s effective from the point of view of application, because control of the engines is simple and RPMs are low. So it’s possible to use traditional vehicle transm ission when asynchronous engine stetted in vehicle instead of gasoline one. As compared to PMSM or BLDC the asynchronous engine has significantly lower efficiency, bigger size and mass but the main disadvantage of asynchronous engine is impossibility of shaft position control. That’s not a problem if engine is connected to transmission like typical gasoline engine and provide torque which is later divided by transmission between wheels, but for the situation when each drivetrain wheel has its own electric engine there appears a problem with trajectory control as sequence of wheels rotation synchronization.

Ev48 technology provides possibilities for precise control of both torque and position of each wheel (or caterpillar) and even undo maximum load, because of using PMSM/BLDC engine and IntEn controller with special algorithms.