Low voltage system with extremely high tractive force for zero rpm

|

When starting the motor we can have the same torque with 48 volts as others with 450 and higher volts |

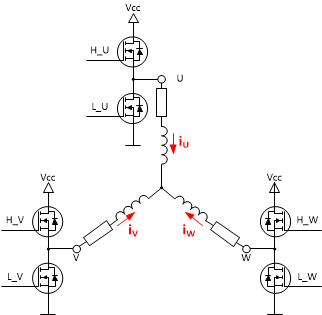

Today’s technology of PMSM or BLDC motors provides high efficiency and precise control of EV transmission by means of PWM formed by invertor based on switches shoulders.

However, the above mentioned approach has two main problems one being with sequencing with each other.

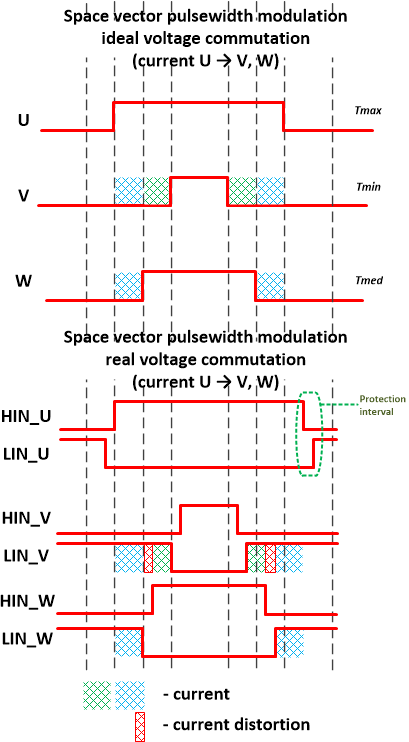

From point of view of torque uniformity and efficiency sinusoidal (or vector) control it’s impossible to provide the most optimal high torque when current in the motor coil is high. This feature is typical for modern inverters control. It’s determined by the necessity to have time gap between turn off and turn on positive and negative shoulder switches in the invertor’s bridge. When the motor doesn’t rotate the resistance of motor coil is low, because of the zero EMF. That means that the invertor low voltage supplement provides situation when time gap is comparable with timing of applicable voltage. As result it’s impossible to control current distribution in the motor coil which means impossibility to control physical shaft position. Thus the user must prevent low voltage supplement for situations when torque is needed immediately after voltage application to the motor coil or when it’s impossible to use high voltage to provide possibility for the motor to reach sensible RPMs before load application.

This problem is caused by the architecture of modern inverters not being oriented on permanent high current supply for the motor coil. Manufacturers don’t see reasons for FEV application to support continuous high current. This area is traditionally occupied by asynchronous motors that can’t provide precise control with high resolution of shaft position and precise control of torque.

Before the EV48 was presented the market never had any caterpillar transporter with 4x4 formula and separate control of caterpillars. Our company has designed the innovative bridge control with System-On-Chip based and the most relative on the planet FPGA we realized absolutely different PMSM control for low RPMs, that provides possibility to get extremely high torque of PMSM/BLDC engine with ZERO RPM. To provide constant low RPM motor rotating and motor start with the load undo we designed special high current adopted architecture and hardware of IntEn controller inverter.